The separation of protein complexes is a critical yet labor-intensive task in biochemical research, typically requiring precise, manual pipetting on hydrophobic membranes. This project, developed by Christopher M. Altenderfer and colleagues at Temple University, introduces an automated device for spotting protein samples onto membranes, optimized for a patented electrophoresis method. This device minimizes user variability and significantly reduces processing time, making it a valuable tool for high-throughput protein analysis.

About the Automated Pipetting Device

The automated pipetting device utilizes a pneumatic system to precisely spot proteins on a hydrophobic membrane, a key step in electrophoresis that is essential for separating proteins and protein complexes. This device is designed to replicate manual pipetting methods while reducing inconsistencies in sample placement, enhancing reproducibility. The automation allows researchers to achieve effective protein separation within a 40-minute process, compared to the one-to-two-day timeline of traditional 2-D polyacrylamide gel electrophoresis.

Key Features

- Automated Spotting Process: Replaces manual pipetting with an automated pneumatic system, ensuring consistent protein sample placement.

- Two Spotting Methods: Incorporates a touch-and-lift method and a plunger method, each offering unique benefits in sample delivery and separation.

- Reduced Processing Time: Completes the electrophoresis process in approximately 40 minutes, significantly faster than traditional methods.

- Enhanced Reproducibility: Minimizes user-dependent variability, ensuring consistent results across experiments.

- Optimized for Hydrophobic Membranes: Designed to work with PVDF membranes, supporting high-efficiency protein separation.

Design and Components

The design of this device is based on key learnings from manual pipetting experiments:

- Touch-and-Lift Method: Uses a pneumatic slide to position the pipette tip just above the membrane, where capillary action draws the sample onto the surface.

- Plunger Method: Applies a forceful downward motion to release the entire sample from the pipette tip, ideal for situations requiring high sample concentration.

- Pneumatic Air Slide and Sensors: The device is equipped with sensors to control motion and ensure precise spotting, essential for reproducibility.

- Hydrophobic Membrane Compatibility: Uses PVDF membranes, which are ideal for electrophoresis due to their low binding affinity and high durability.

Cost and Accessibility

Developed as a laboratory tool, this device requires standard lab equipment and components, making it accessible for research institutions. Funding from The Nanotechnology Institute supported the project’s development, contributing to its feasibility as an affordable, reproducible solution for protein complex separation.

Performance and Results

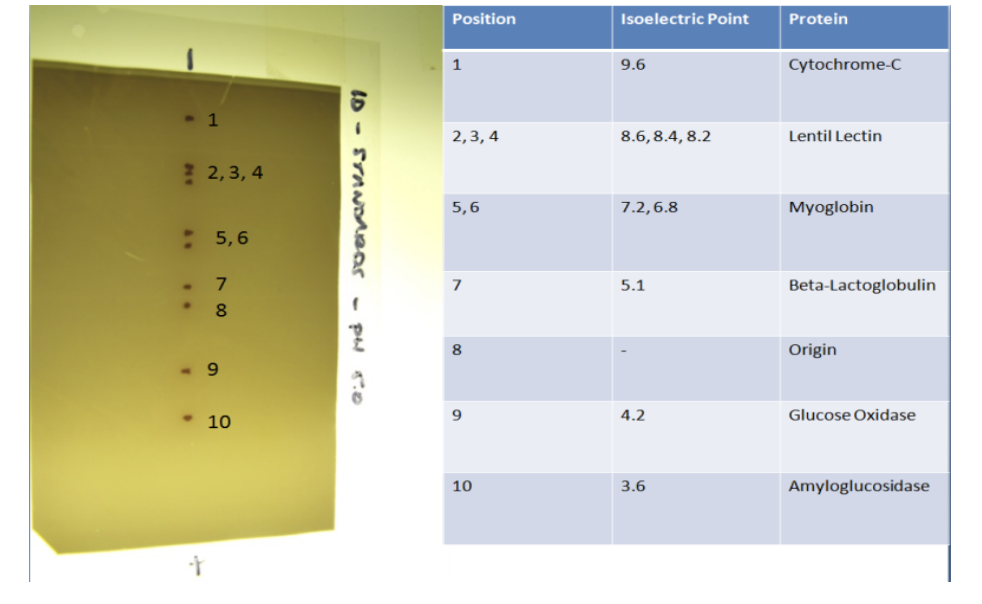

The automated device replicates the conditions of optimal manual pipetting, consistently achieving effective protein separation. Initial testing with a six-protein mixture confirmed the device’s ability to separate proteins by isoelectric point, with enhanced reproducibility compared to manual techniques. The device’s design minimizes binding issues by controlling contact area and force, essential factors in high-quality protein separation.

How to Use the Automated Pipetting Device

- Load the Sample: Place the protein sample in a Pipetman P2 pipette, using a 0.5 µL sample with a 50/50 water-ε-caprolactone solution.

- Position the Membrane: Place the PVDF membrane on the spotting surface, secured for consistent positioning.

- Select Spotting Method: Choose either the touch-and-lift or plunger method based on sample and experiment requirements.

- Start the Device: Activate the pneumatic slide, which will spot the sample in a controlled motion.

- Electrophoresis Process: Transfer the spotted membrane to a low-conductivity buffer, adjust the pH, and apply voltage for five minutes.

The device’s intuitive design simplifies complex protein separation steps, allowing for high-throughput applications and improved consistency in research outcomes.

The automated pipetting device for protein complex separation presents a significant advancement in electrophoresis. By automating the spotting process and optimizing sample placement, this tool addresses the challenges of manual pipetting, offering a reproducible, efficient, and user-independent method for protein separation. This device is an invaluable resource for biochemical and molecular biology research, reducing time and enhancing accuracy in protein complex studies.