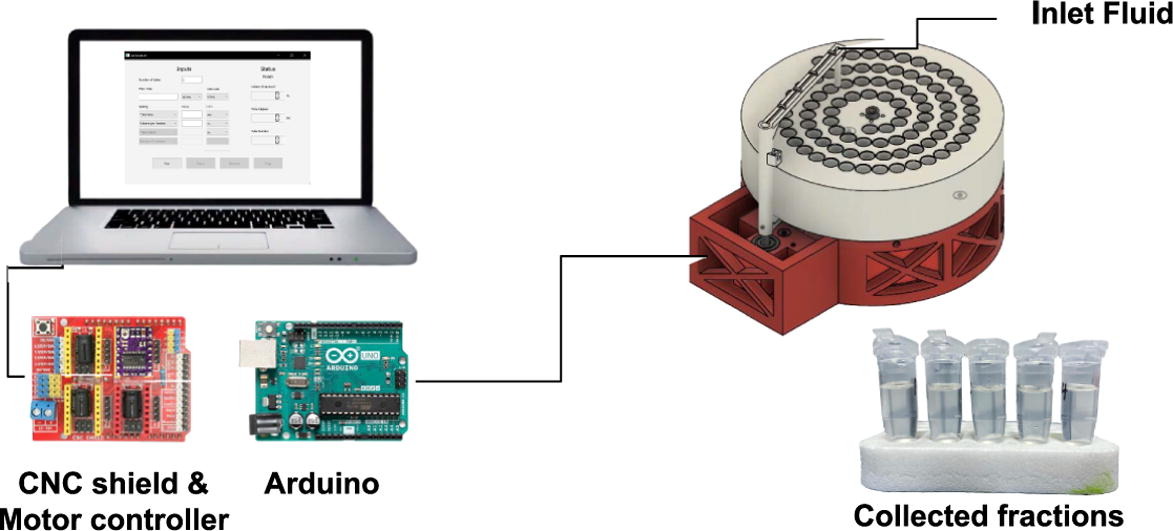

This paper presents the Colosseum, a low-cost, modular fluid sampling device designed for scalable fluidic applications. The Colosseum can be assembled from off-the-shelf components and 3D-printed parts for less than $100, making it an accessible solution for laboratories. Its design allows for easy operation and customization, providing researchers with an efficient method for automated fluid collection.

Key Features

- Affordable: Total hardware cost is approximately $67.02, significantly lower than commercial alternatives.

- Modular Design: Each component can be developed and assembled separately, facilitating easy repairs and upgrades.

- Single Motor Operation: Utilizes a single motor for controlling the entire sampling process, simplifying the mechanism and reducing complexity.

- Automated Control: Operated through a graphical user interface (GUI), enabling programmable fluid sampling for various applications.

- Open Source: Design files and source code are freely available, allowing for modifications and improvements by the community.

Specifications

| Specification | Details |

|---|---|

| Device Name | Colosseum Fluid Sampling Device |

| Cost | $67.02 |

| Assembly Time | Less than 1 hour |

| Fluid Sampling Capacity | Up to 88 samples (1.5 mL Eppendorf tubes) |

| Power Supply | 12 V DC |

| Control Software | Python-based GUI, also available in a web version |

| Open Source License | BSD-2 |

| Source File Repository | GitHub Repository |

Build Instructions

- 3D Print Components: Use the provided STL files to print the necessary parts.

- Assemble Electronics: Integrate a stepper motor, Arduino, and motor controller as specified in the design.

- Modify the Fluid Collection Setup: Adjust the configuration to fit various tube sizes based on experimental needs.

- Connect to Power and Control System: Ensure proper wiring and connection to the Arduino for control.

Operation Instructions

- Prepare Tubes: Insert collection tubes into the spiral tube layout.

- Set Sampling Parameters: Input desired flow rates, total volume, and fraction size into the GUI.

- Start Sampling: Run the sampling protocol, monitoring real-time progress through the GUI.

Validation

The Colosseum was tested for accuracy in fluid sampling, demonstrating consistent collection rates and minimal errors across various flow rates, making it suitable for diverse fluidics applications.

The Colosseum fluid sampling device offers a practical, low-cost solution for automated fluid collection in laboratory settings. Its open-source design and scalability make it an excellent tool for researchers seeking to enhance their experimental workflows.